Our high-quality plastic profiles offer unrivalled sliding properties that facilitate optimum rolling and unrolling thanks to their extremely low frictional resistance

The warnings of global warming are also an issue for manufacturers of sun protection systems such as awnings. They must ensure that the functionality and durability of their devices will fulfil the stricter requirements of the future. The plastic profiles, which are concealed in slide rails or roller mechanisms and ensure that the systems function smoothly in every sense of the word, also play a key role here. When it comes to upgrading your products, it is advisable to contact us as early as possible. Our experts can help you design future-proof materials and manufacturing processes.

Fig. 1: Elegant, discreet and weatherproof cassette awnings installed on the façade provide shade for outdoor seating areas, terraces or balconies as needed.

Fig. 2: Shell-shaped lining to guide the fabric in a cassette awning. The material selected here is temperature- resistant and weatherproof with good sliding properties and high abrasion resistance.

Awnings provide shade for balconies or outdoor seating areas such as patios. An important plastic profile here is the guide shell in the cassette, over which the fabric glides when it is wound or unwound (Fig. 2). The main requirements for this scenario are good sliding properties so that the fabric can be easily wound or unwound. Abrasion resistance, UV and ageing resistance are equally important properties. The guide shell should also protect the fabric from damage caused by potential burrs and chips that may result from the processing or installation of the metal awning box.

The guide shell ensures that the awning can be extended and retracted smoothly. This must not result in discolouration of the fabric, e.g. due to abrasion.

In some cases, static charges must also be avoided. In such situations, the profile can be produced as a coextruded profile with antistatic properties.

The solution shown in Fig. 2 was offered to a customer as part of the development of a new product. The selected material was a blend of polyolefins, a temperature and UV-resistant material with very good sliding properties.

The decision in favour of the solution we offered was mainly due to the sophisticated design, which was adapted to the geometry of the aluminium profile to save material and therefore costs. The simple and safe installation was also convincing. In this development, our experts were able to make full use of their long-standing experience and materials expertise. We also prevailed over the competition because our solution was economically more favourable.

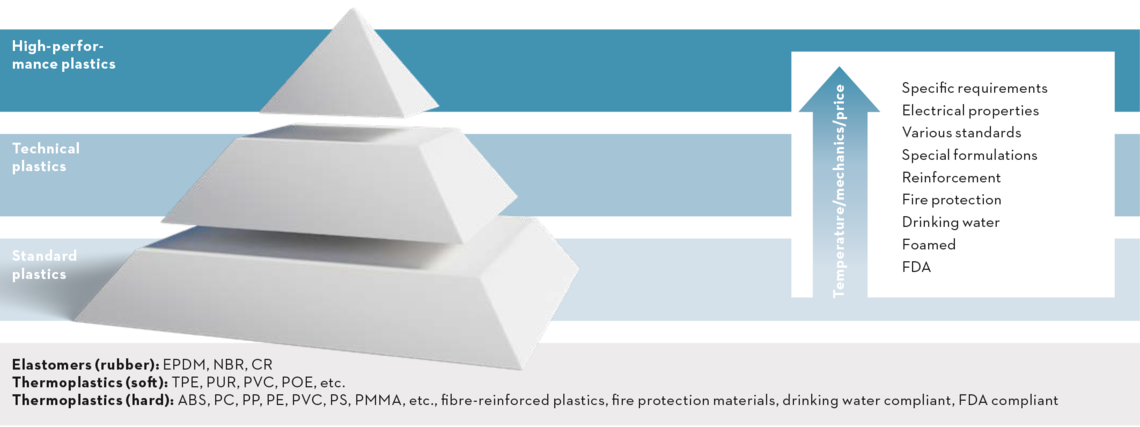

The experts at mobil Kunststoffprofile can draw on extensive experience in selecting the best material and the right process. After analysing the customer’s requirements and special requests in detail, we work with the customer’s experts to develop proposals and, if necessary, create test batches. Naturally, the relevant standards, test regulations and statutory requirements are also taken into account and the necessary certificates are issued.

Legislators at EU level are increasingly tightening the reins to reduce CO2 emissions. As part of regular reviews by specialised rating agencies, all large companies are required to keep their ESG (environmental, social and governance) rating as high as possible via the financial market and public clients. This also includes constant pressure on the company’s own suppliers to demonstrate compliance with the relevant requirements. An important criterion here is the documentation of the so-called ‘carbon footprint’. This means balancing the CO2 emissions generated by the company’s activities. Besides the direct and indirect CO2 emissions caused during the company’s own production process, this also involves the CO2 emissions already indirectly contained in the purchased materials (through previous production steps). Here too, our specialists have extensive experience in reducing emissions compared to the previous state of the art. Depending on the requirements specification and choice of material, we can utilise alternative materials with a lower CO2 emissions backpack or supply sources with a demonstrably lower-emission process chain. The consistent use of recycled materials plays a key role here. We will gladly advise you here too.

High weather resistance

The plastic profiles used are UV and temperature resistant as well as weatherproof.

Optimised sliding properties

Good sliding properties ensure smooth retraction and extension of the awning.

Lower costs

Thanks to the material and cost-saving design of the profile, the solution is impressively cost-effective.