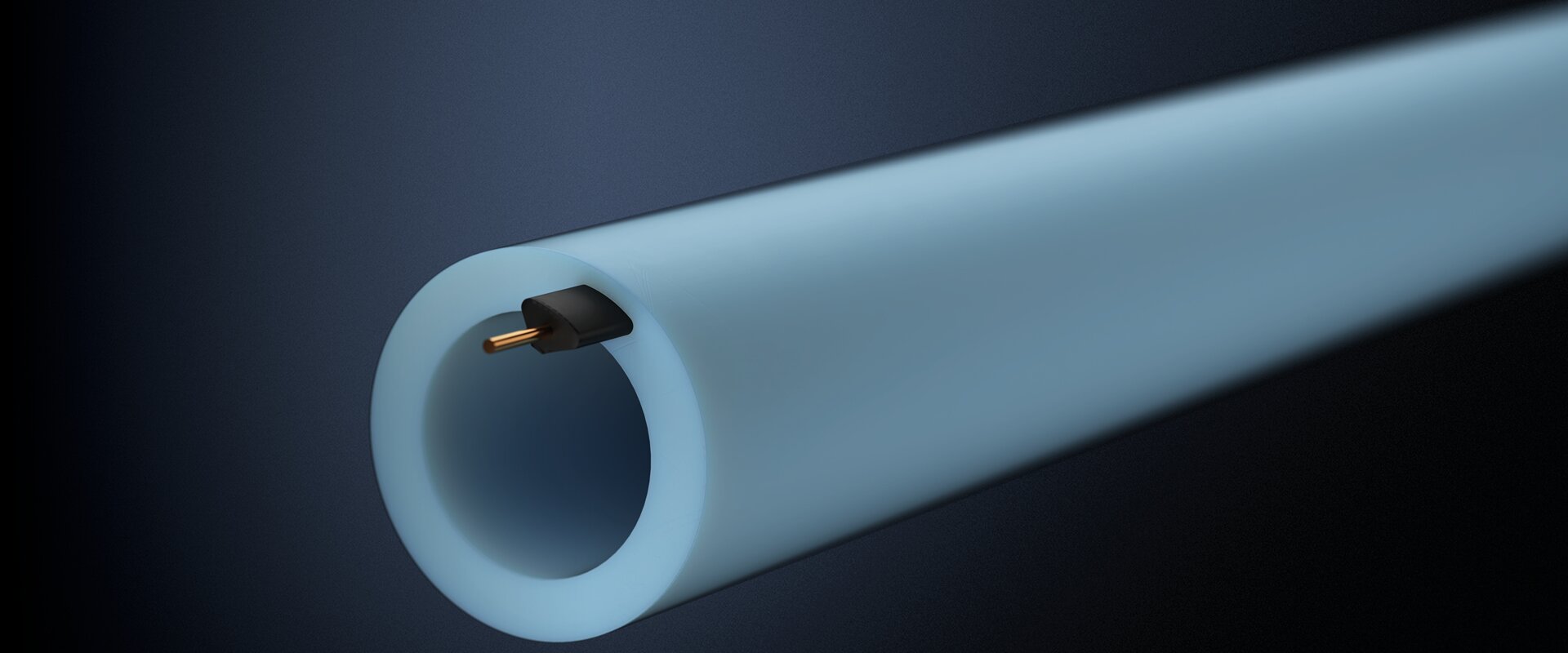

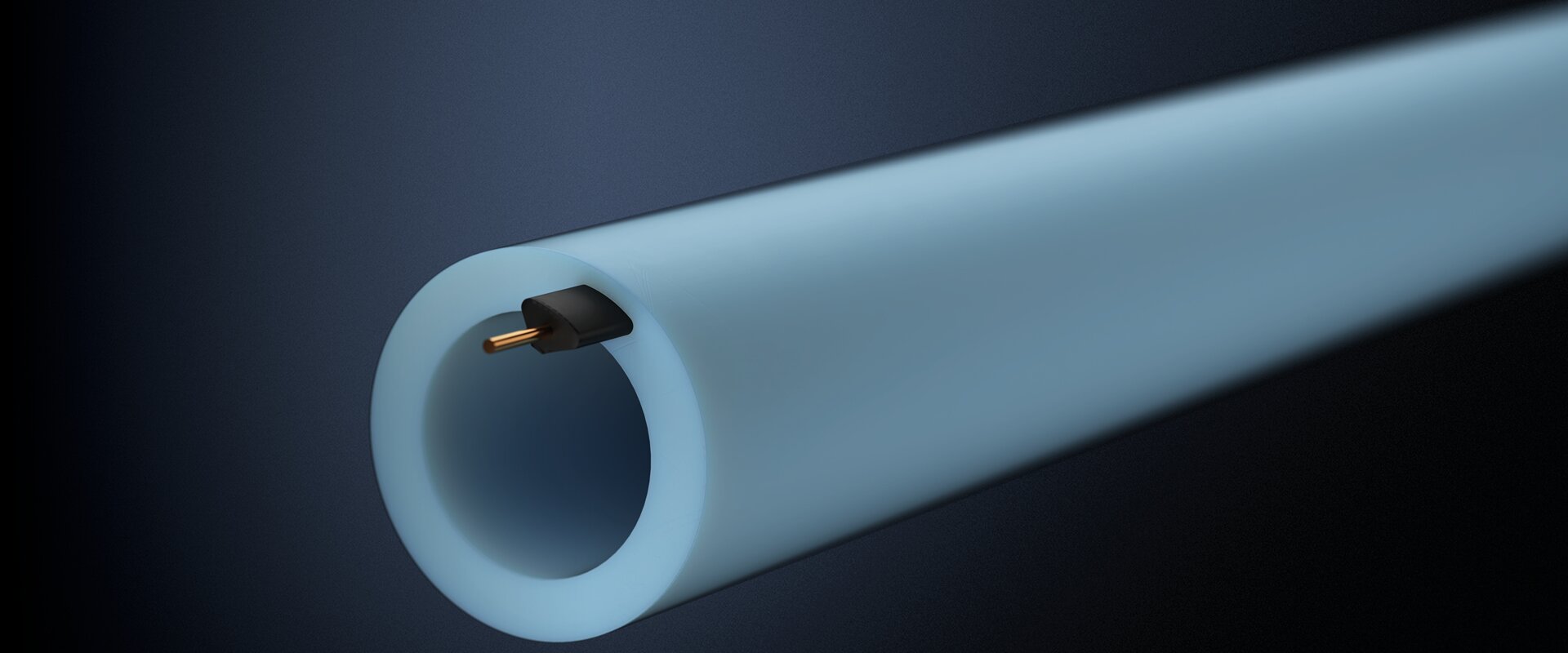

Plastics have very good electrical insulation properties by nature – but certain applications demand exactly the opposite. This can easily be achieved with the correct modification of the material. This enables various electrically conductive, antistatic or even static dissipative properties to be established. We’d be happy to support you with our know-how in developing plastic profiles that precisely match your application to your conductivity requirements.

The term ESD (“Electrostatic Sensitive Device” or “Electrostatic Discharge”) is often used when referring to the reduction of charge differences or the transmission of electrical signals or currents. In both cases, the focus is on protecting electronic components; in practice, however, the prevention of voltage breakdowns in explosive environments (EX area) or when handling flammable substances is often meant or understood. The high conductivity of metal cannot be achieved with plastics, except for intrinsically conductive polymers. However, certain compound systems allow for a semiconducting range where a pulse can travel short distances.

Permanent and non-permanent systems can be used in the antistatic field. The mode of action of non-permanent systems is based on the binding of humidity. They lose their desired property when they are wiped off or when the deposit is used up. To achieve permanently conductive properties, plastics are modified with suitable fillers. Conductive carbon blacks and graphites are commonly used for both conductive and semi-conductive systems. This gives modified plastics their typical black colour. Other possibilities are carbon or metal fibres as well as electrically conductive pigments.

The conductivity that can be achieved depends on the formation of the filler network. Depending on the type, shape and concentration, the filler particles come into contact with electricity and thus conduct the current. The processing of the material also plays a decisive role in the formation of the network. So, for example, the orientation of the fillers, the temperature control as well as the formation of the injection moulded surface (injection moulding as well as extrusion) have a major influence on the property. As an experienced partner for conductive plastics, we are happy to assist you in developing and producing profiles according to your requirements.

The following materials are particularly suitable for optimising the conductive properties of plastics. mobil Kunststoffprofile has already used these several times for customer projects:

Modification

Depending on the application, the conductive property of plastics can be specifically adapted.

Safety

When developing conductive profiles, we pay special attention to norms and safety standards.

Know-how

There is a lot to consider when processing plastics. We have the relevant experience.