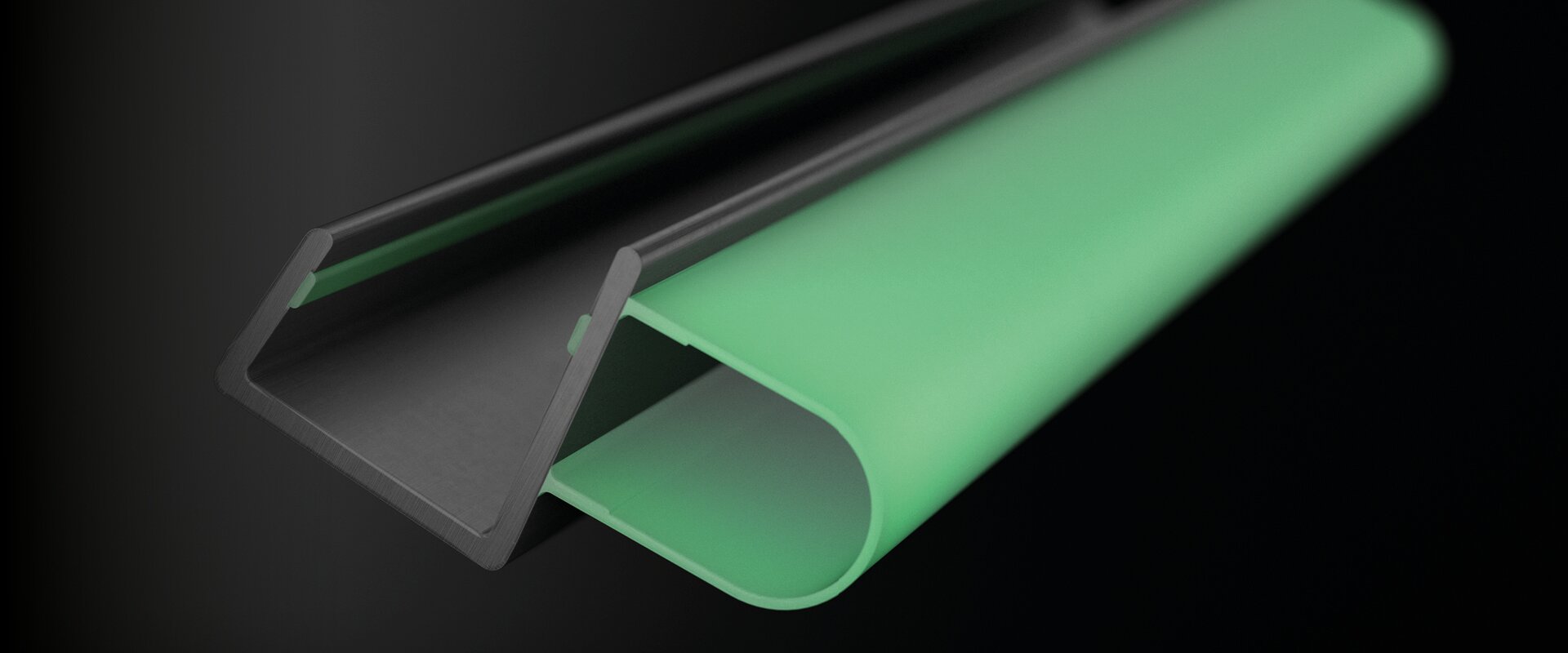

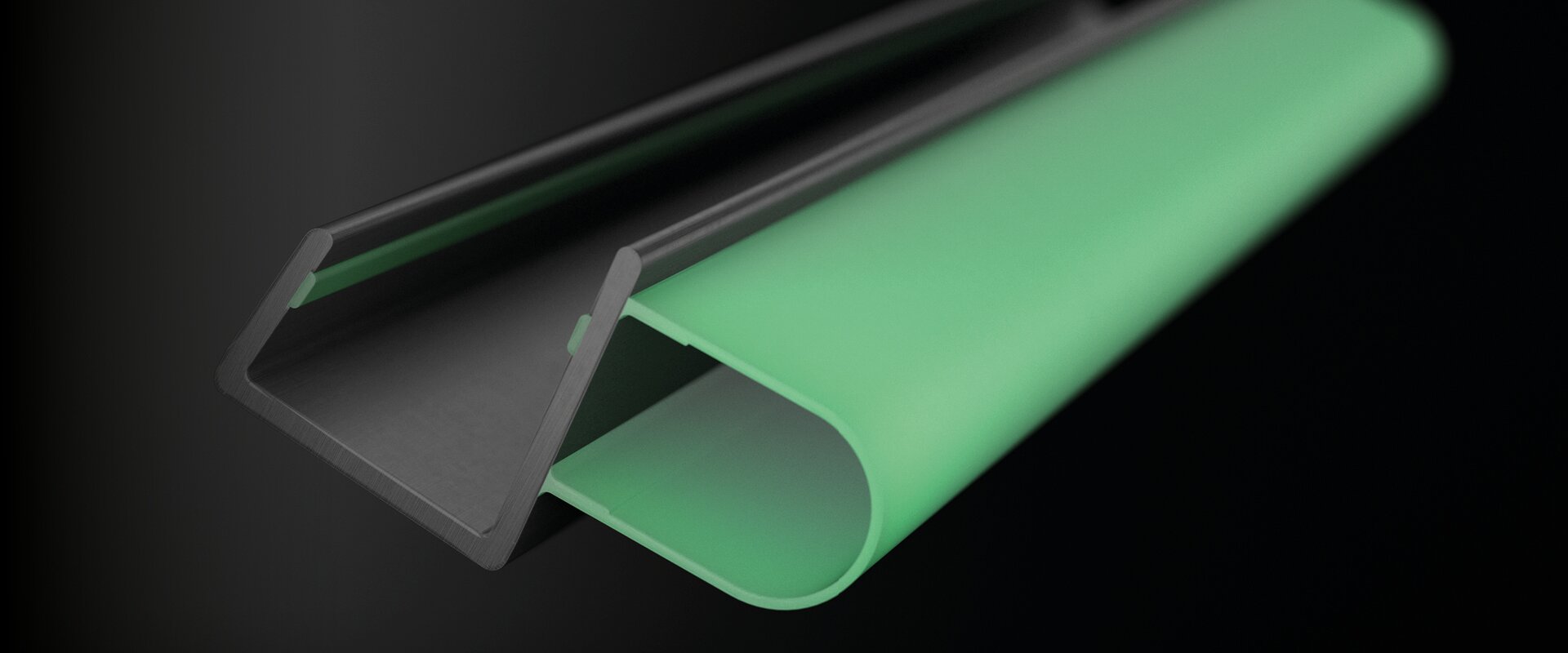

Strong together: coextrusion combines two or more materials with different properties in one profile. Melted in different extruders, these materials are brought together in the tool. Common applications of the coextrusion process are combinations of hard and soft materials or multi-coloured solutions. The advantages for profiles are very diverse and come into play in various industries.

Coextrusion has already been used by mobil Kunststoffprofile in a number of customer projects, and in particular for profiles that need to perform well even in challenging conditions – for example, water deflectors in dishwashers that need to be completely leak-proof and should not leak water even when opened. However, we not only support you in the development and production of the profiles, we also show you finishing options to help you optimise your processes and thus save system costs.

The coextrusion process lets you combine many different materials. The following combinations of material or material properties are used particularly frequently at mobil Kunststoffprofile:

Know-how

mobil Kunststoffprofile has already used coextrusion for a wide variety of customer projects.

Material diversity

Plastics with various properties can be used as required.

Cost reduction

Coextruded profiles can reduce system costs in many applications.