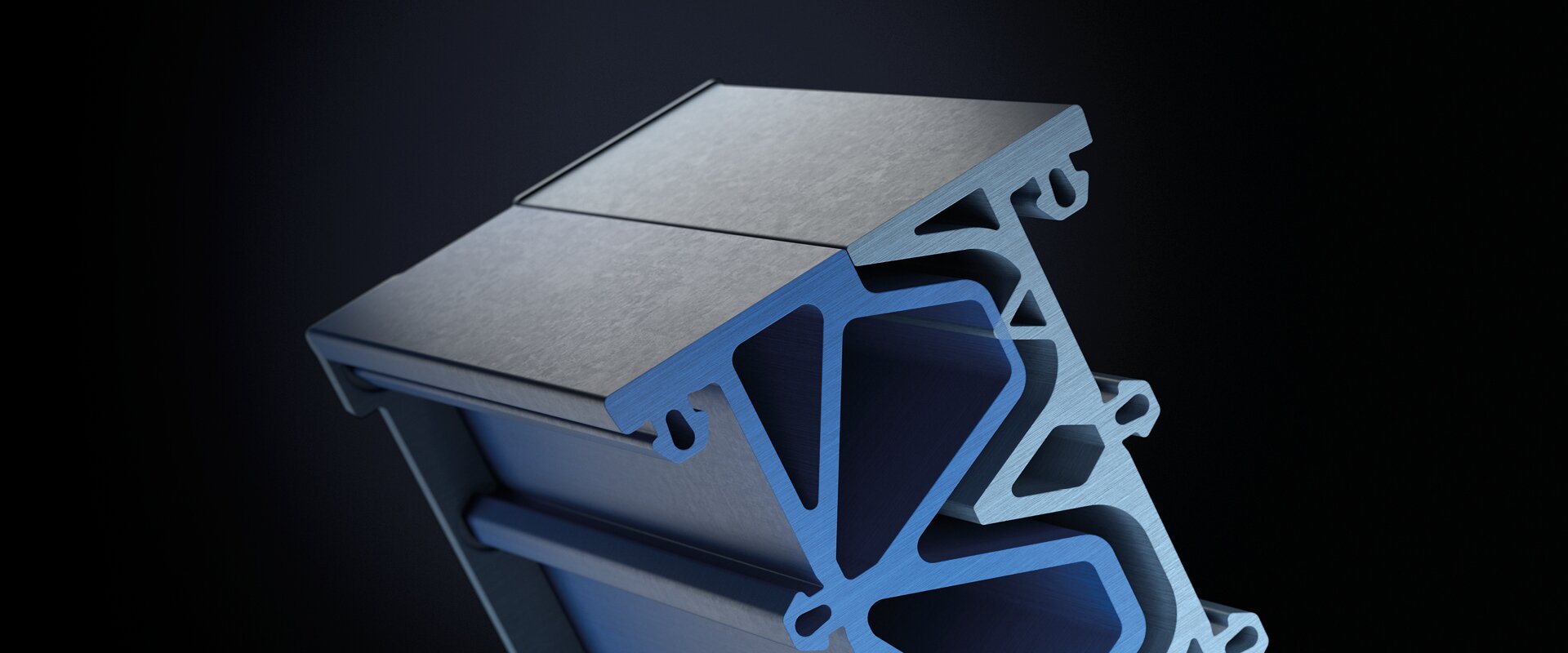

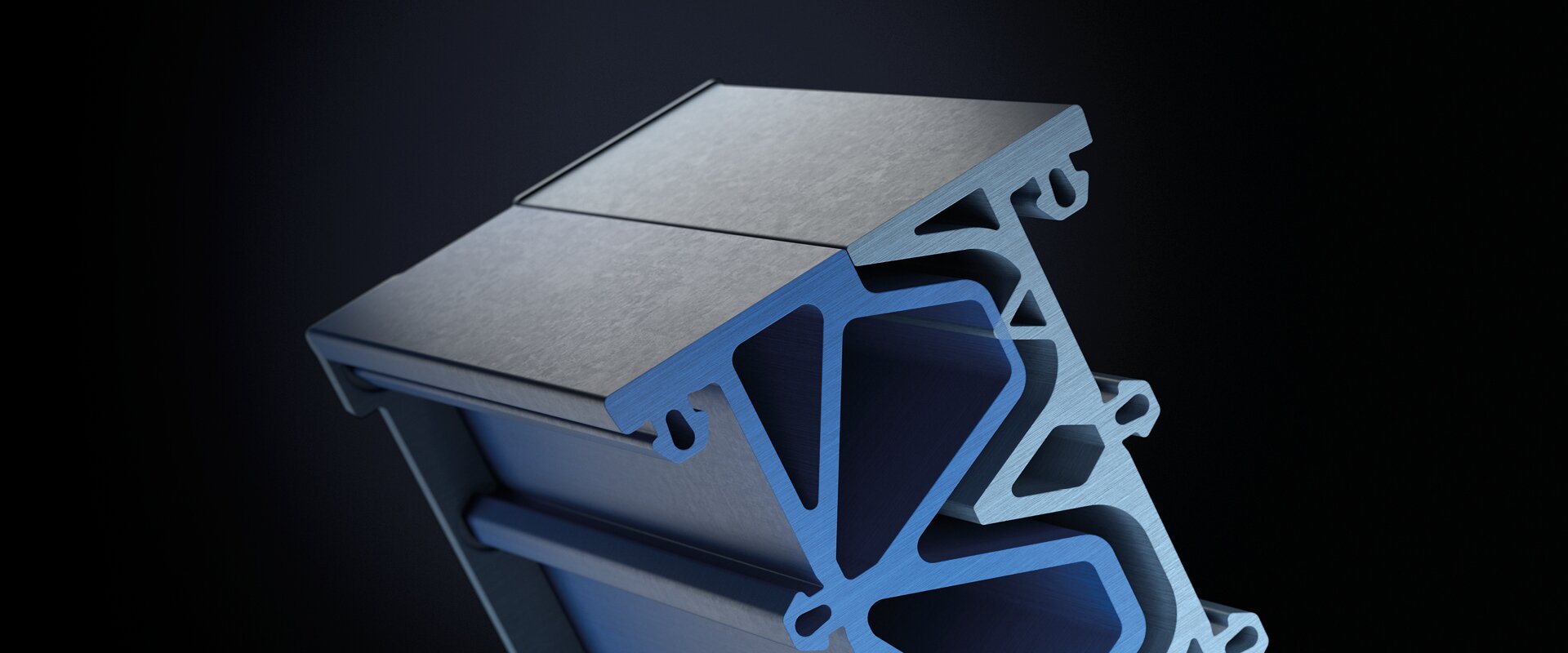

Concentrating on your own strengths and outsourcing plastic finishing work is a good idea and a good way to increase your own productivity. We’re your partner for custom plastic cutting, punching, drilling, labelling, embossing and much more. We always make sure that we get actively involved. This has enabled us to optimise profiles for our customers on several occasions and to integrate fabrication directly into the production process of the profiles or seals.

We have our own machinery for standard fabrications such as vulcanising corners, punching or applying adhesive tape. This means we can realise orders efficiently and to a high standard. Even when outsourcing to us, the multifunctionality and individualisation of your products are ensured using the comprehensive options provided by inline processing (sawing, drilling, punching, embossing, printing) and offline processing (welding, adhesion, vulcanisation, component assembly). For us, made-to-measure plastic is just as valid for small series as it is for large orders.

Increasing efficiency

Your productivity increases by outsourcing the finishing process

Individuality

Thanks to the wide range of design options, products can be completely individualised.

Large and small series

We assemble individual components as well as large series.