Seals for manhole covers in drinking water supply systems must meet the highest standards. Together with the customer, mobil Kunststoffprofile has developed and produced a new type of seal that not only guarantees complete impermeability but also reduces the assembly time and thus significantly increases the margin of the after-sales business.

The customer carries out regular maintenance work on manhole covers. The replacement of seals was a time-consuming process (as they had to be glued) with corresponding costs that could not be passed on to the end customer. A seal therefore needed to be found that could be fitted without using glue. The customer was not satisfied with the quality of the glue joint on the previous seal either: if leaks occur the groundwater can be contaminated. In winter, ice can form, causing the seal to fail. Finally, the material must also comply with KTW certificate no. 1.313.

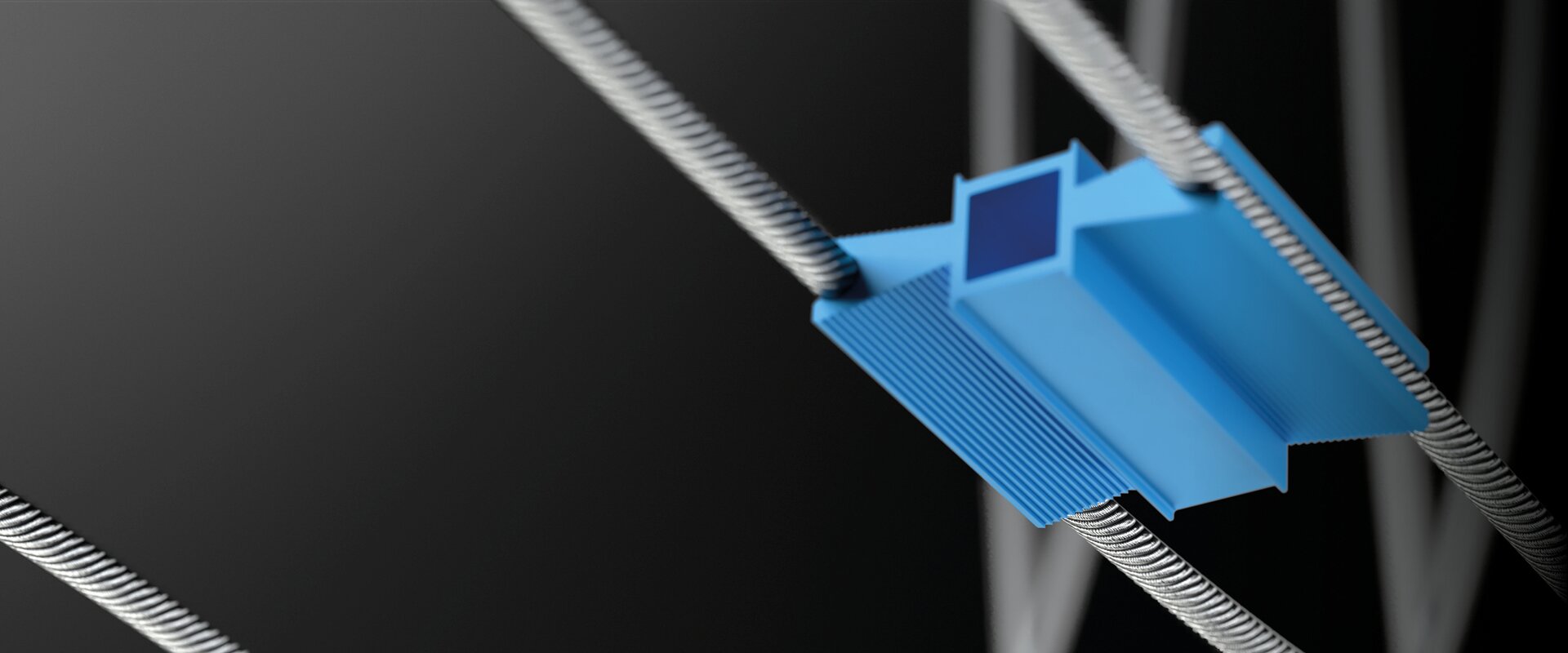

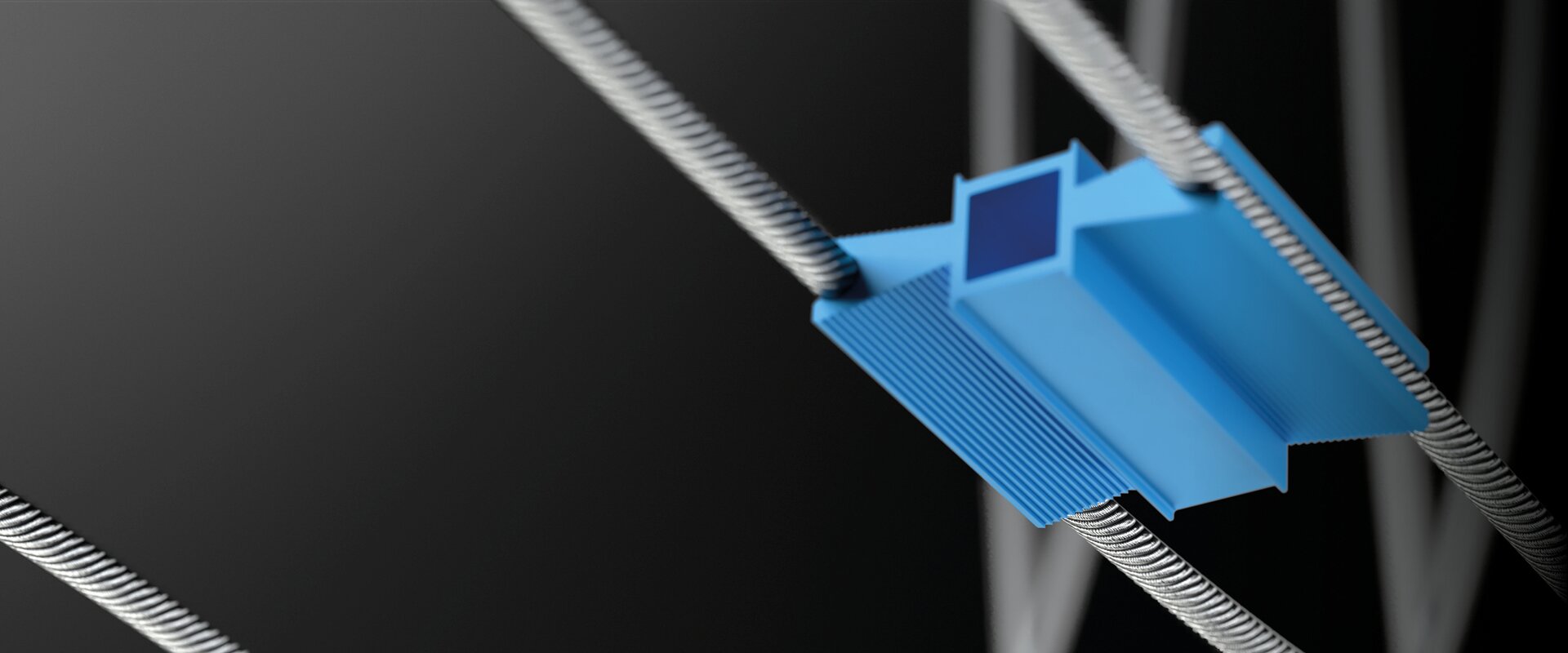

mobil Kunststoffprofile created an initial design proposal based on these specifications. This design proposal was further optimised with the customer to allow the sealing surface to better compensate for unevenness. Simplifying the profile contour also made it easier to glue the profile together to form a sealing ring.

Reduced after-sales costs

The on-site installation time is halved from 90 to 45 minutes.

Fewer tools

The installation no longer requires primers or adhesives.

Faster installation

No gluing required – the seal is placed directly onto a metal ring. This assembly is then mounted on the housing cover only using screws.

Increased reliability

Thanks to the simplified sealing contour, the seal now works reliably, even in winter.

Attractive expansion of the range