The call for safety is getting louder. Consequently, the demands on the components and their functions are increasing. When it comes to fire safety, plastics have a lot to offer and need to fulfil strict criteria regarding fire behaviour, smoke development and flaming droplets. Flame-retardant plastics are being used more and more frequently – in buildings, vehicles or in equipment housing – in order to keep the risk to human life and incidental damage as low as possible in the event of fire. Also, thanks to our development of “Fireblock”, we’re the perfect partner for fire protection solutions that have been established in practice.

Optimising the fire behaviour of plastics with the right materials requires an in-depth understanding of plastics. Flame retardants are additives that limit, slow down or prevent the spread of fire. They are incorporated in the compounding process: either in small or large quantities, depending on the type and requirement. However, the greater the proportion of additives, the more likely they are to reduce the physical properties of the plastic. Finding the middle ground here is a challenge that we are always happy to take on.

Flame retardants work in different ways, but several mechanisms usually occur simultaneously. These have the following effects:

We use a range of materials as flame retardants – halogenated and non-halogenated. The advantage of the halogen substances chlorine and bromine is that even a small amount is very effective. This is why brominated flame retardants enjoy great popularity and account for the largest share in terms of value. However, these substances are sometimes controversial because they emit high concentrations of dioxins (high toxicity) in fires. Alternatives include metal hydroxides (ATH and MDA), which are the most widely used flame retardants by quantity. The conversion process to water vapour causes the substrate or combustion gas to cool. Other compounds may include phosphorus, nitrogens, boron and zinc compounds as well as graphites and miscellaneous flame retardants.

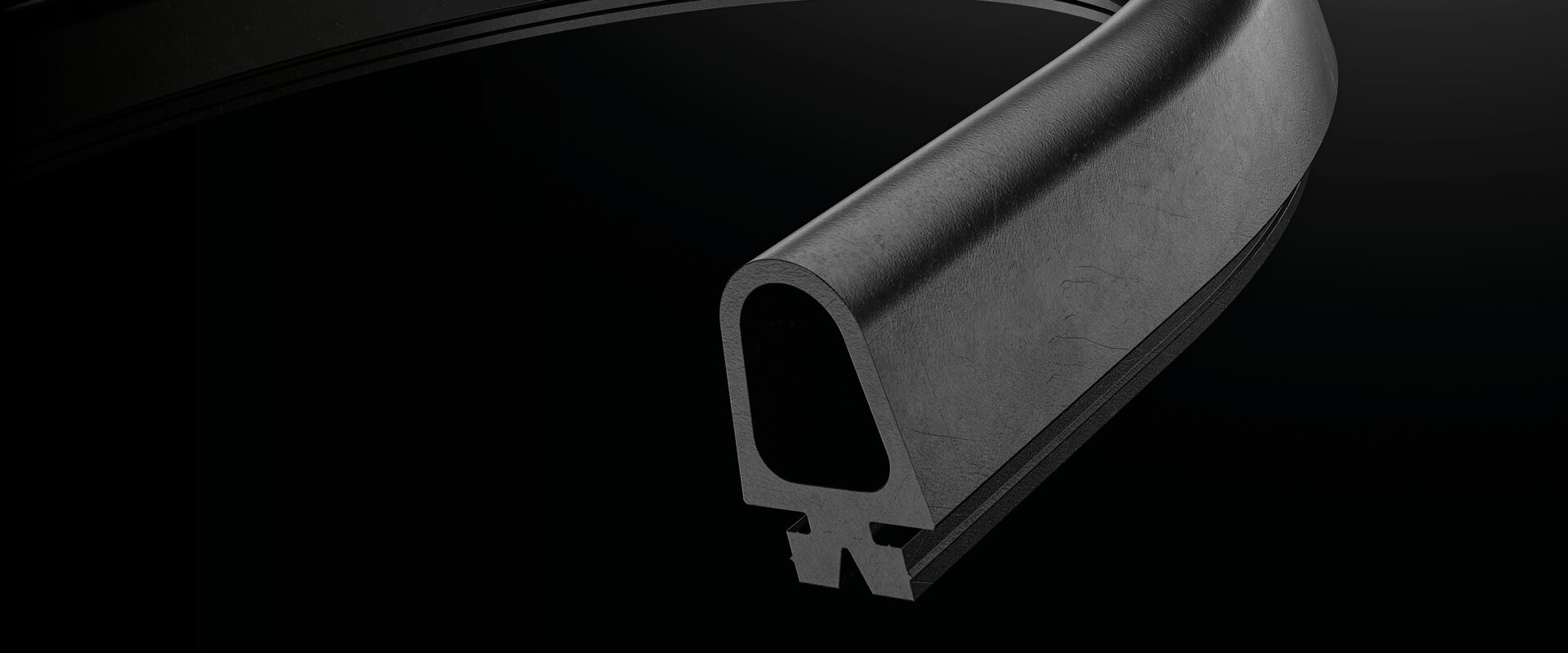

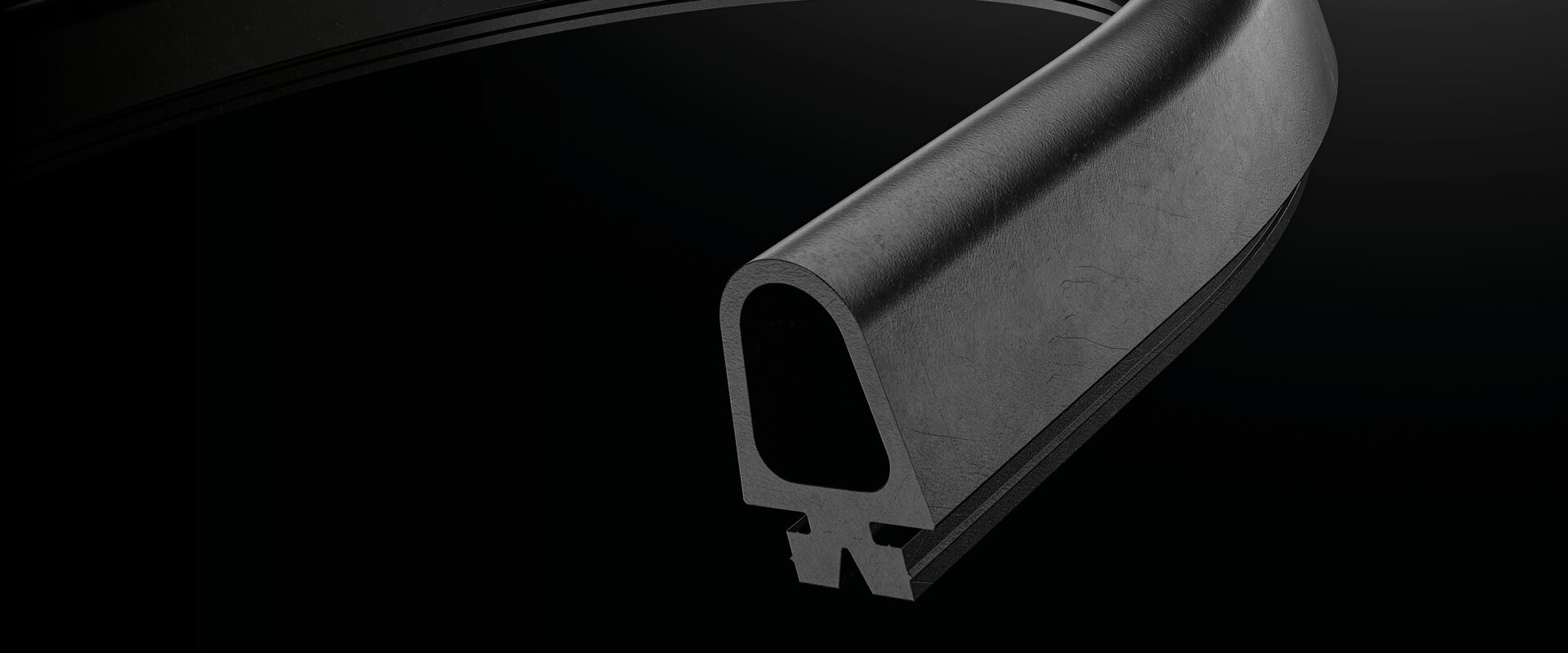

“Fireblock” developed by mobil Kunststoffprofile for demanding fire protection applications is a milestone in the fire protection market. The material has the unique property that it can be extruded into any shape and as a multi-component profile. In addition, “Fireblock” is designed in such a way that it can be individually adapted to the needs of each customer in terms of expansion factor and reaction time. This means:“Fireblock” offers immense innovation potential for your products.

“Fireblock” is an intumescent material that develops into a foamed mass when exposed to heat and acts as a “heat brake”. The oxygen supply and the spread of the flame is hindered over a certain period of time. In simple terms, the formation of the foamed mass works as follows: the expandable graphite contained in the material releases gases through the heating effect, which increases the volume of the mass and decreases the density. The expansion of the foamed mass exerts pressure on the adjacent components, which is also known as “expansion pressure”. In the event of a fire, foaming offers the following advantages:

“Fireblock” provides an application-oriented fire prevention seal according to the fire prevention requirement, taking into account the reaction temperature, expansion direction, expansion volume and expansion pressure. mobil Kunststoffprofile has gradually gained this unique experience over the past few years in a wide variety of development projects. “Fireblock” is certified in category E according to DIN EN 13501 fire behaviour.This certification demonstrates a high level of conformity with DIN 4201 B2, DIN 5510 Part 2 and UL94 V0.

Properly combined, various materials can be used for fire protection profiles and seals. The following materials are often used for fire protection profiles from mobil Kunststoffprofile:

Protection against damage

Fire protection seals protect people as well as buildings, goods, etc.

Adhering to standards

When developing fire protection solutions, we pay special attention to applicable standards.

Know-how

With “Fireblock”, mobil Kunststoffprofile developed a material for demanding fire protection applications.