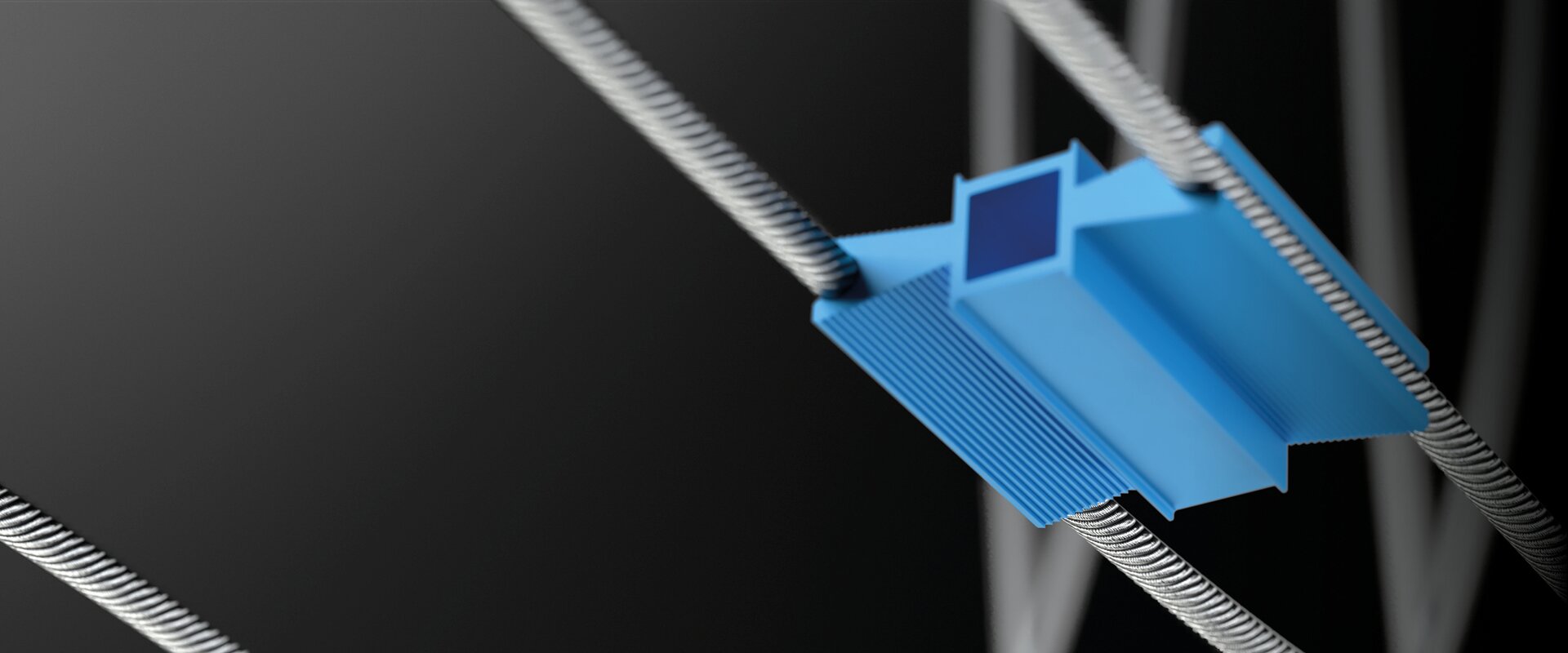

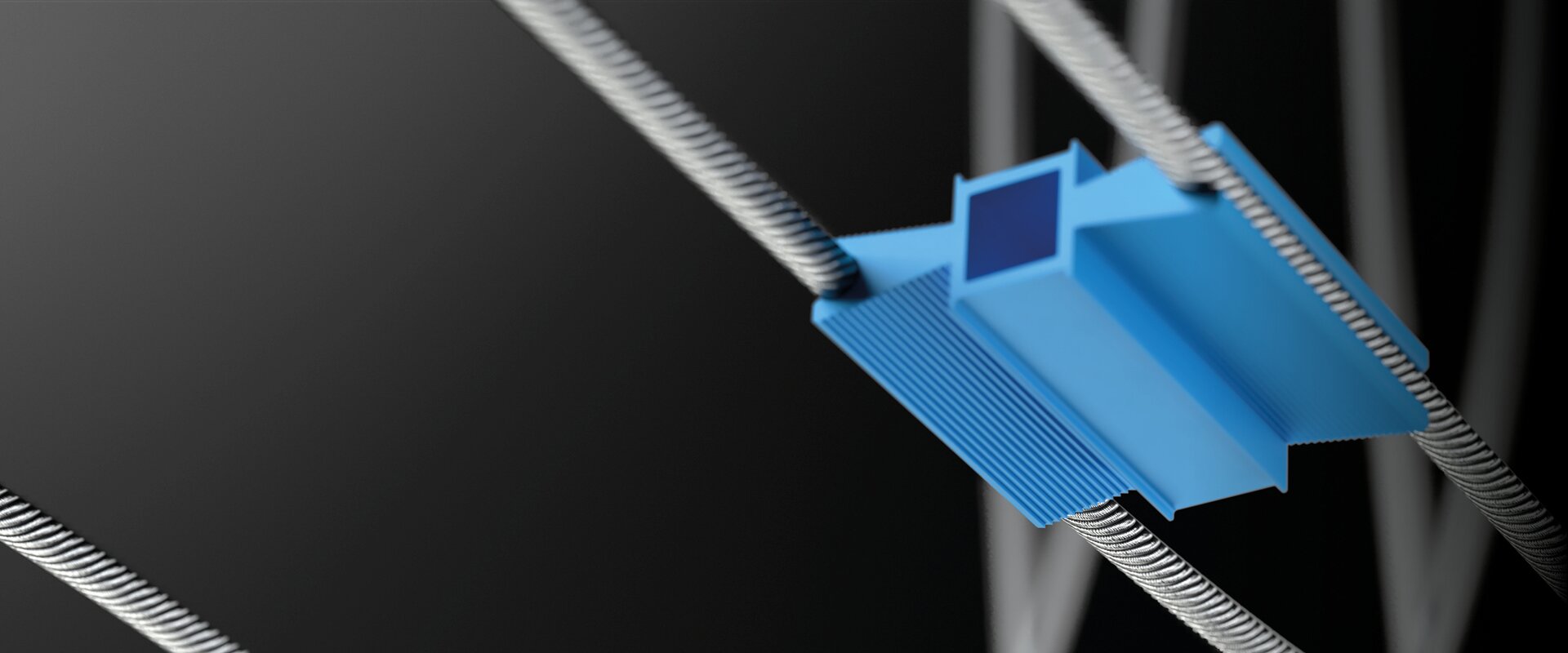

Profiles often have to withstand high, recurring loads, for example in entrance mats in dirt traps. They ensure cleanliness, safety and value in buildings and should aesthetically blend into the surroundings. mobil Kunststoffprofile optimised an existing tread profile for a company that manufactures entrance mat systems for frequently accessed entrances. The result: lower system costs and easier assembly.

Initially, the customer used a tread profile made of resistant EPDM. It fulfilled the functional load requirements, but when it was installed in the aluminium rail, the tread profile – despite having sufficient tolerances – ended up expanding, sliding beyond the aluminium rail and contracting again. The profile had to be installed in the rail with extra length and then cut to size once again.

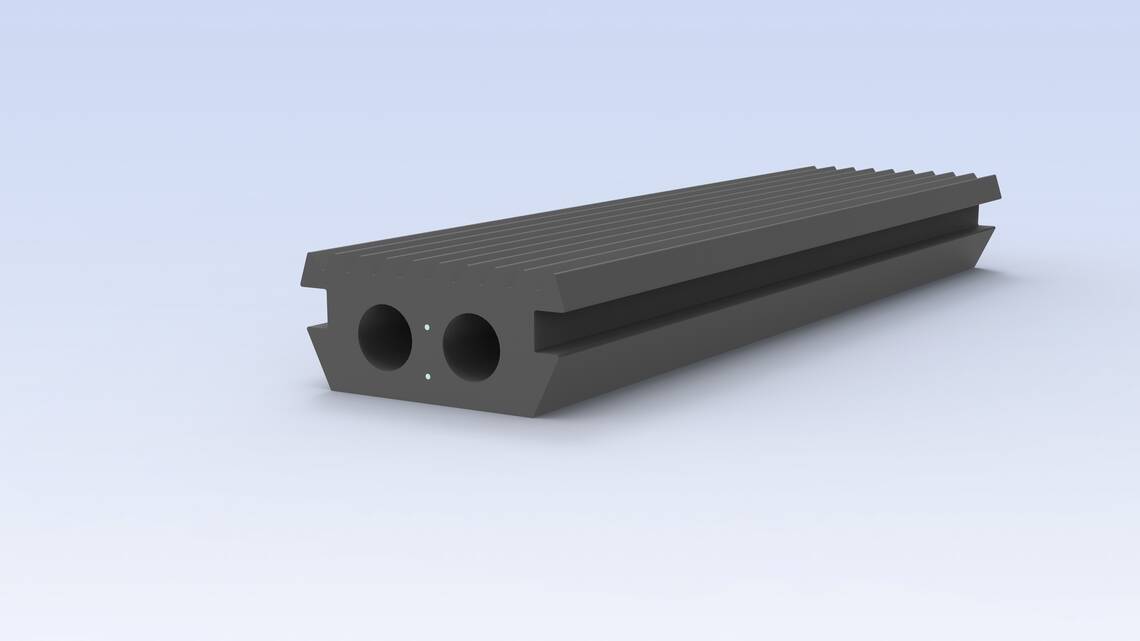

mobil Kunststoffprofile evaluated a solution with the customer and proposed the use of an anti-stretch device consisting of two high-quality polyester threads. The stretch protection could be integrated into the existing tool with little effort. This now prevents the tread profile from expanding during installation and then retracting again.

Lower system costs

The installation costs are 20% lower thanks to the reduced number of processing steps; the waste costs are also 5% lower.

Broader range of applications

The customer successfully uses the optimised tread profile in other fields of activity.