Time is money, especially when launching product innovations in growth markets and when undertaking prestige projects. An international manufacturer of door and gate systems was looking for a special door seal with end cap for a new type of door system shortly before a launch in the Far East. A tailor-made solution was created using mobil Kunststoffprofile’s considerable expertise in materials and processing as well as flexibility. The product impressed the end customer.

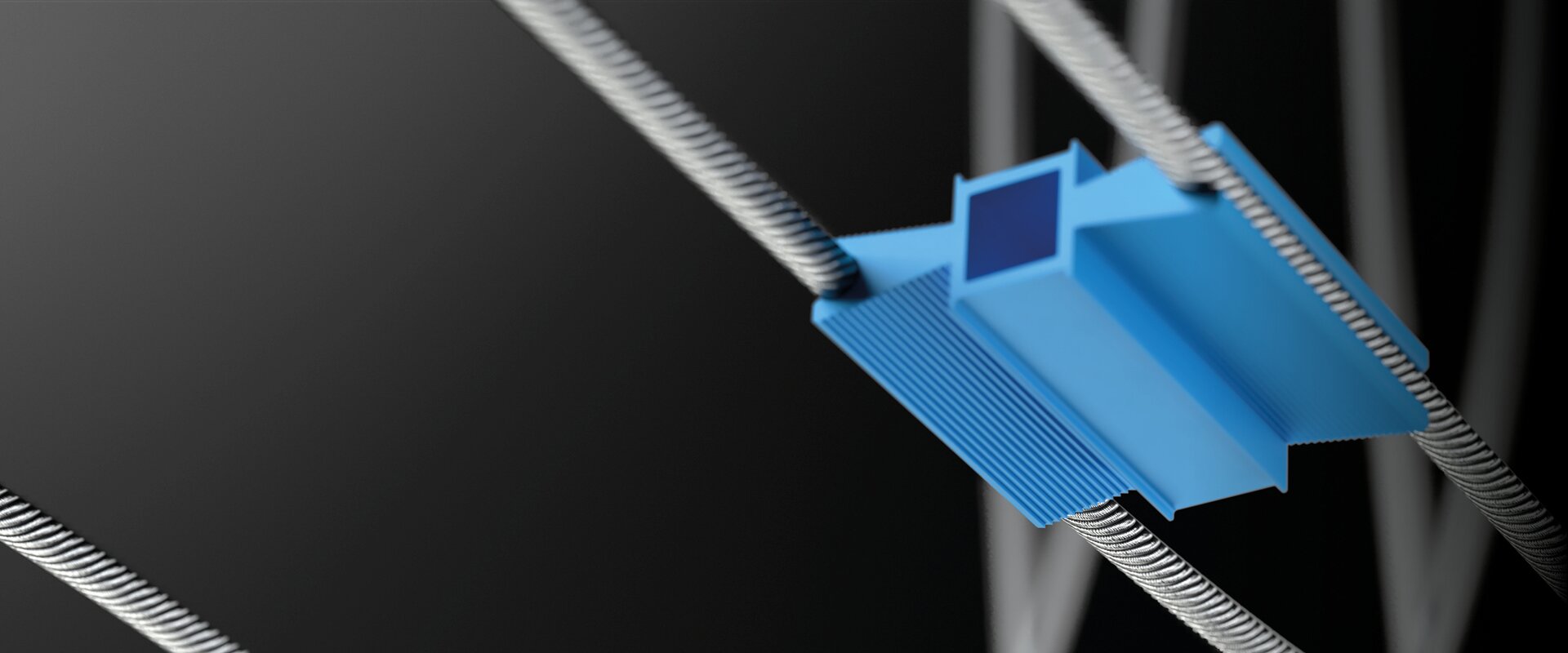

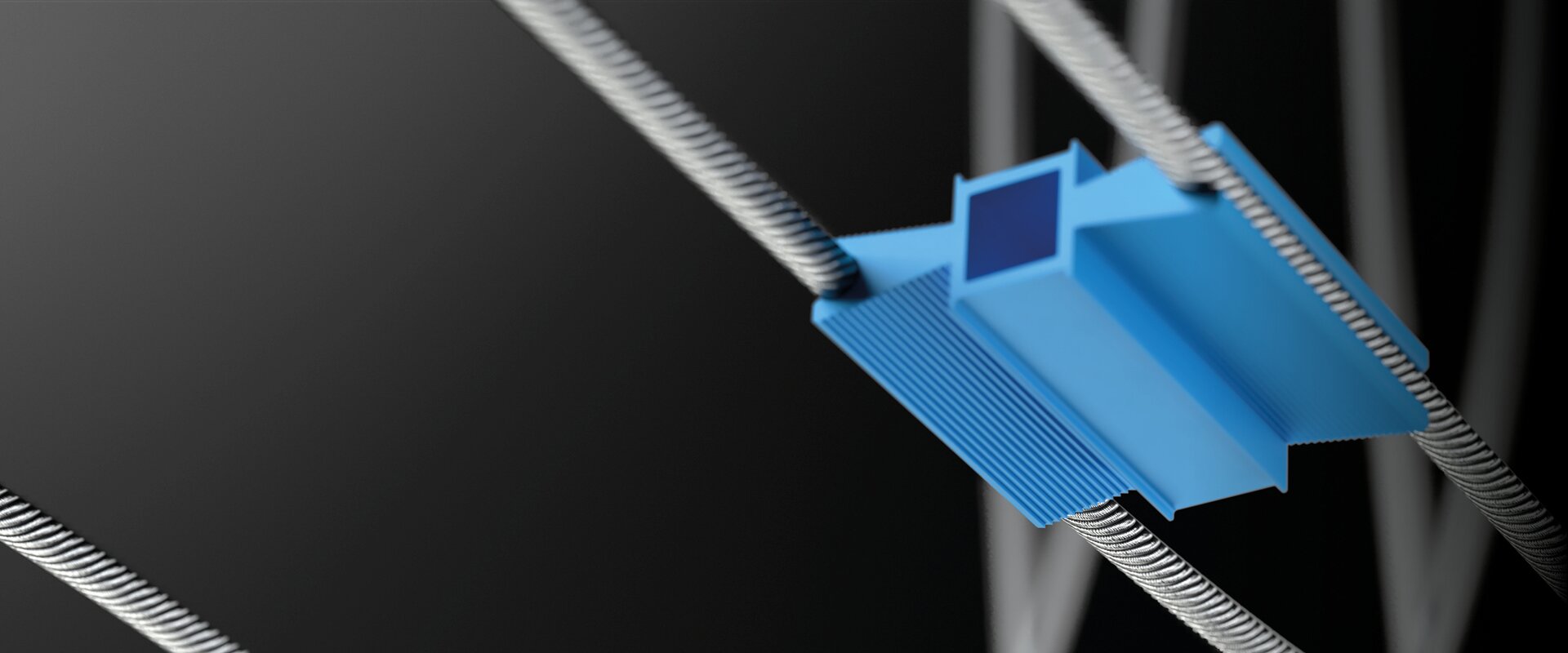

The customer lacked the right door seal for a new type of door system that was to be used for the first time in an important project in Hong Kong. This was to be made of high-quality CR rubber. The development and production time was estimated at just a few weeks. Furthermore, an additional challenge arose during the development phase – the end caps also had to be developed and manufactured for the door seal.

This project required a wide range of skills, from development and material expertise, to extrusion and elastomer injection moulding. It was important to establish short communication routes with the customer during this process, e.g. for comparing drawings, toolmaking, sampling and seeking approvals. The outturn samples were delivered on time after just five weeks.

Everything from a single source

The customer receives a customised, ready-to-install assembly.

Prompt execution

The shortest possible development and production times enabled the customer to successfully “go to market”.

Active knowledge transfer

Thanks to the close, intensive cooperation, the customer expanded its knowledge in the design of end profiles.