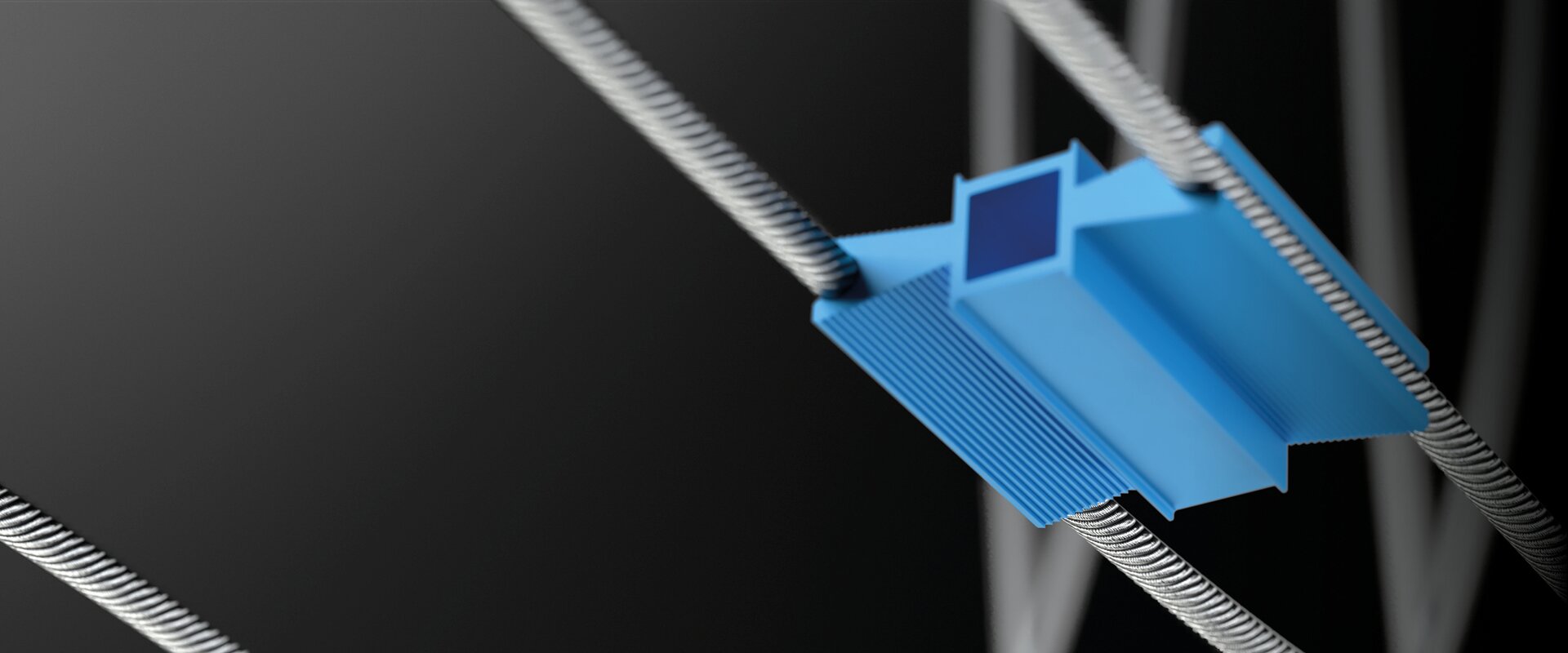

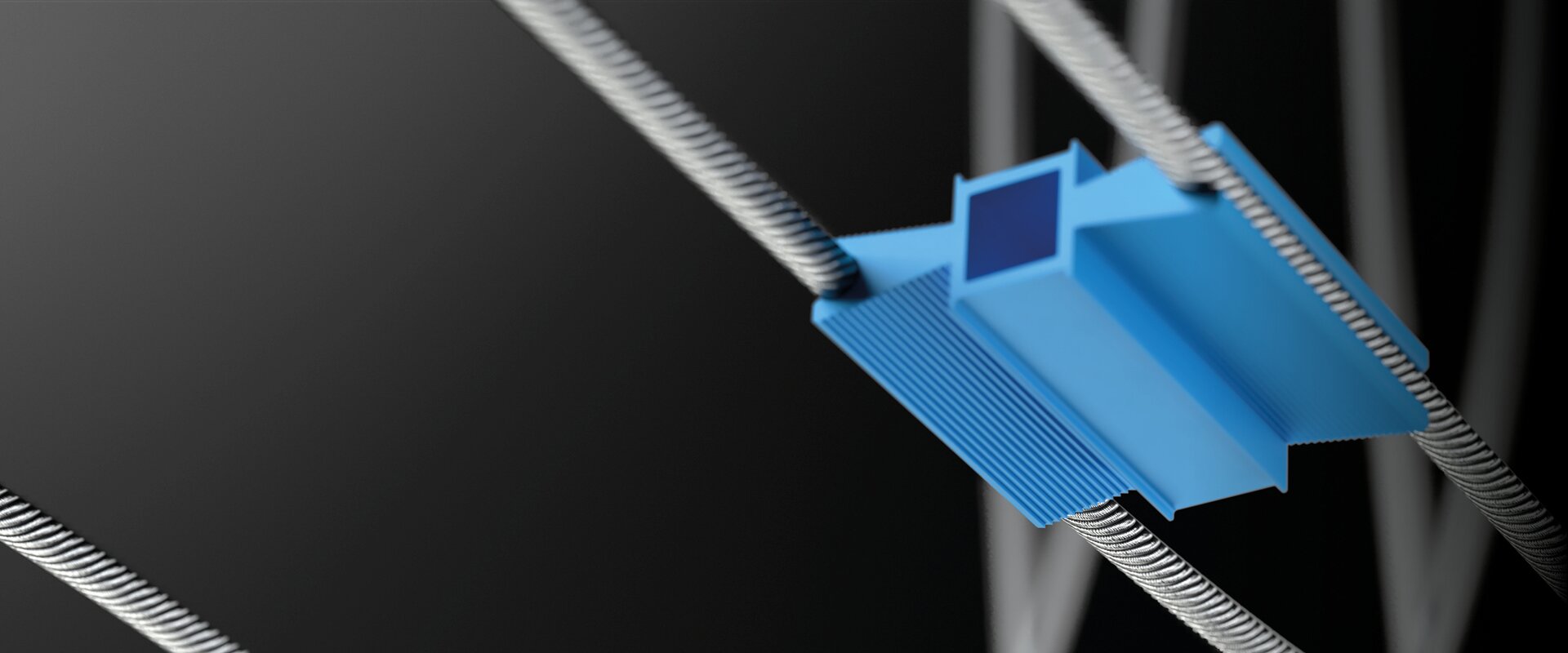

A manufacturer of quick-clamping systems used to obtain its sealing profiles from a standard catalogue. However, these profiles only partially fulfilled the precision, efficiency and process reliability required for mechanical machining centres. mobil Kunststoffprofile focuses its developments on elastomers and enables the customer to use sealing rings in precisely fitting lengths thanks to ring vulcanisation.

In addition to vulcanisation and flexible ring size, the seal had to be oil and temperature resistant, have a hardness of 70 – 85 ShA and reliably seal with a stroke movement of 2 mm without exceeding the defined value for the force required. Important for maintenance: easy assembly and tight fit so that the seal is not blown out of the groove when cleaning with compressed air.

The geometry was worked out in CAD based on initial profile drawings. The specifications were then drawn up and finally the new sealing profile was sampled. For the joint sampling, the first profile rings were bonded and, after passing the test, the tool for ring vulcanisation was implemented.

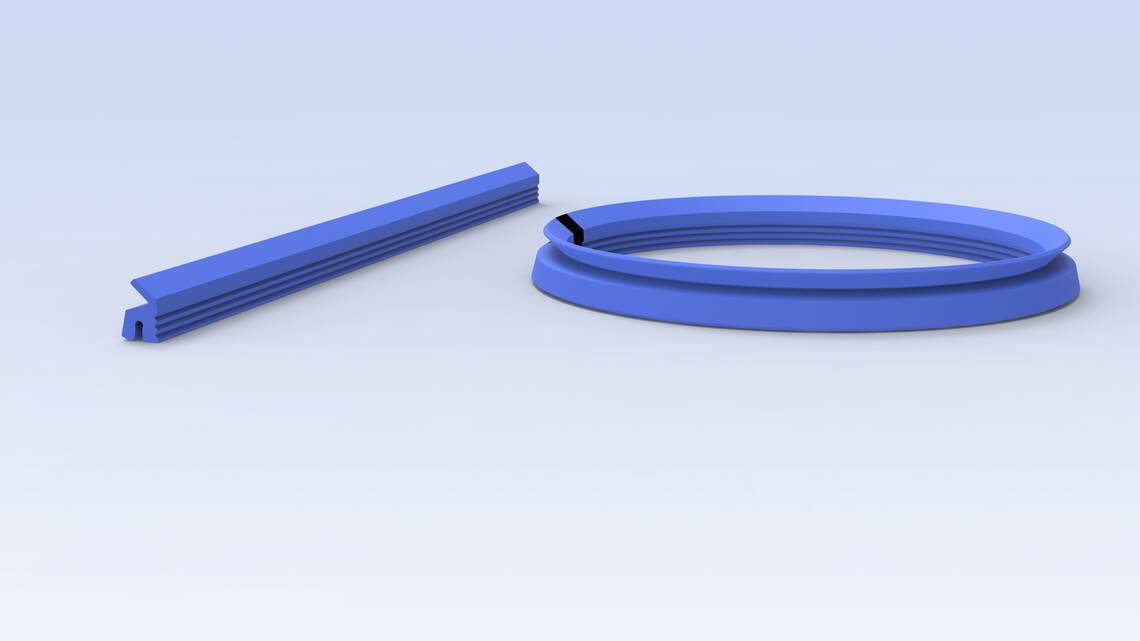

High flexibility

Sealing rings of different sizes can be produced with one profile.

Lower system costs

The investment in tools and sampling is more than a third cheaper than moulded articles. Only one profile and vulcanisation tool is required to make various sizes.

Optimised procurement

The two-stage manufacturing process (profile production and ring vulcanisation) enables larger batches to be produced with a cost benefit of up to 40%.