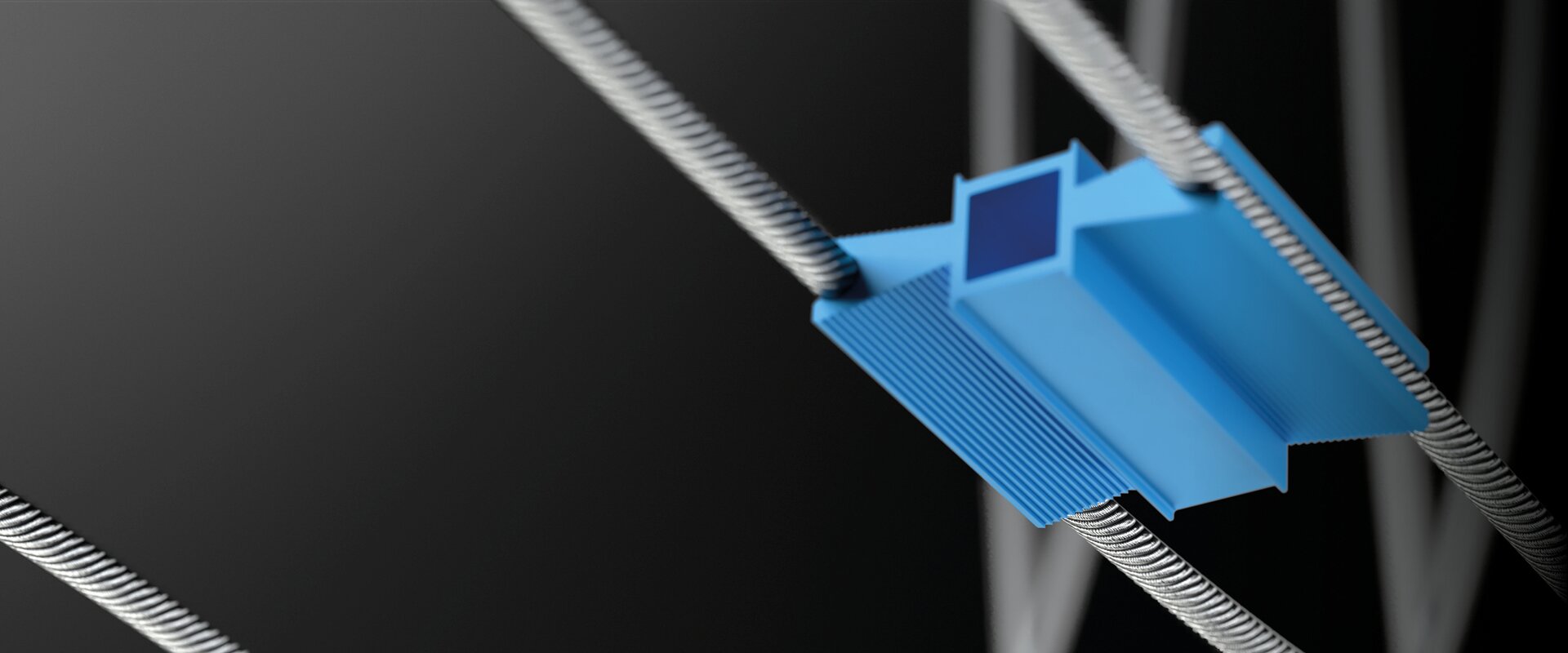

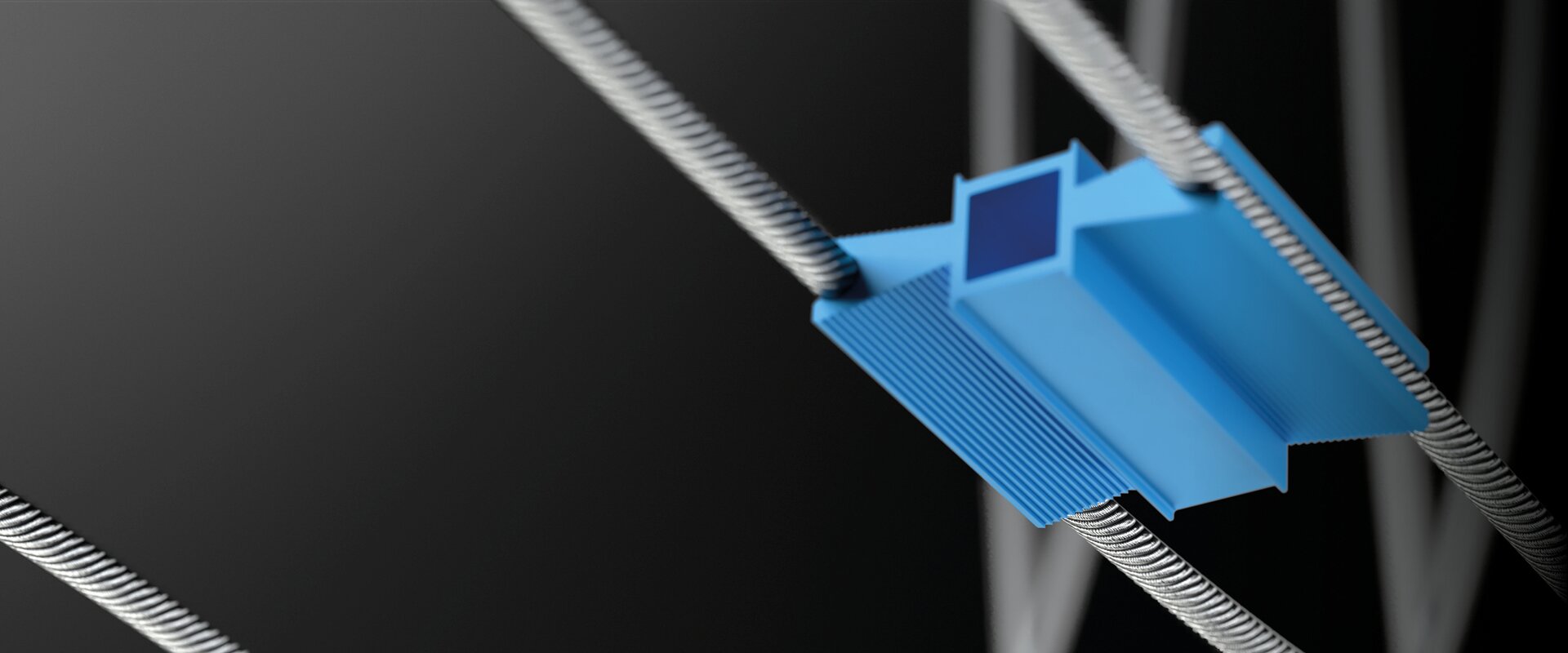

Not visible, but noticeable to man and machine – the climate in closed rooms. A leading manufacturer of ventilation and air conditioning units for comfort and productive environments was looking for a high-performance profile to achieve a better climate. They found what they were looking for at mobil Kunststoffprofile. The cooperation resulted in a newly developed, application-specific profile for thermal insulation.

In energy systems, every component plays a conductive role. The customer's requirements for the new profile therefore placed high demands on the developers and process engineers at mobil Kunststoffprofile. On the one hand, the air content of the profile had to be as high as possible and it had to achieve better thermal conductivity. On the other hand, the profile had to be prestressed to make it fit tightly into the housing and easy to manually attach to a steel plate using a snap-on connection. Also self-evident, but challenging in terms of production was the fact that, despite the different wall thicknesses, the profile had to meet the required mechanical stability and straightness.

Any procedural issues that arose from the desired functionalities were solved step by step in close cooperation with the customer. It is particularly important to determine the ideal foaming level in this process so that the profile achieves the specified lambda value while remaining dimensionally stable. The result is a foamed ABS profile that comes under the specified cost limit.

Energy effect

The functionality and design of the newly developed profile fully meet the application requirements.

Expansion of the range

The profile is an essential part of a new generation of equipment and underlines the customer's innovative leadership.

Short development time

Cooperating with the supplier early on was a move that paid off with development to sampling taking just 25 working days.