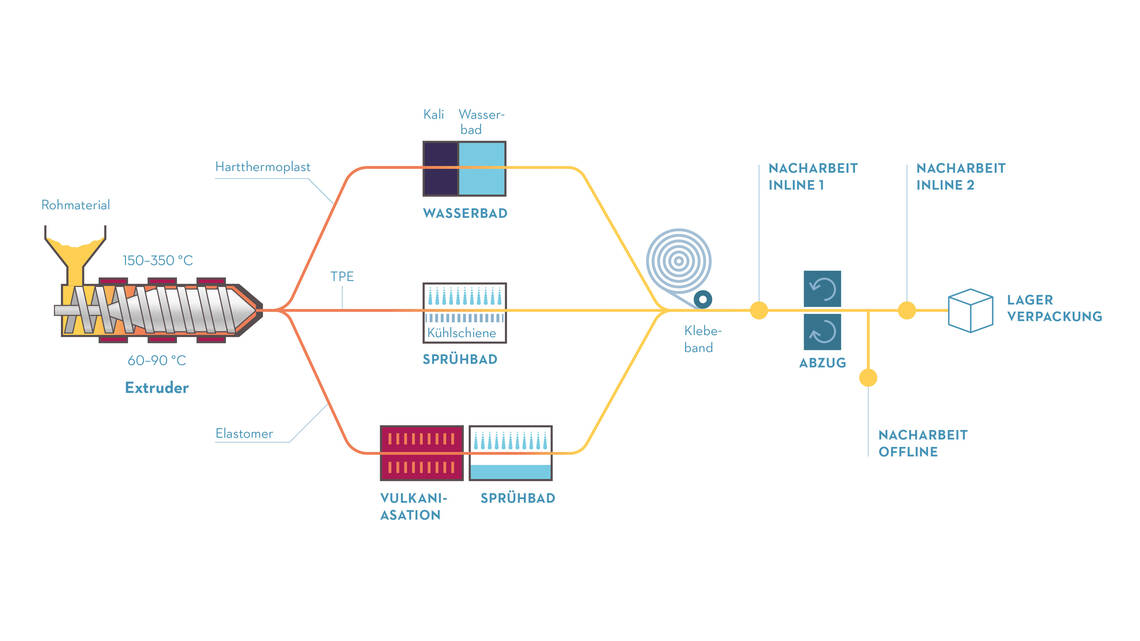

Profiles and seals are produced using an extrusion process. Depending on the material used, a different machine setup is required. We are familiar with the various requirements and consistently focus on them.

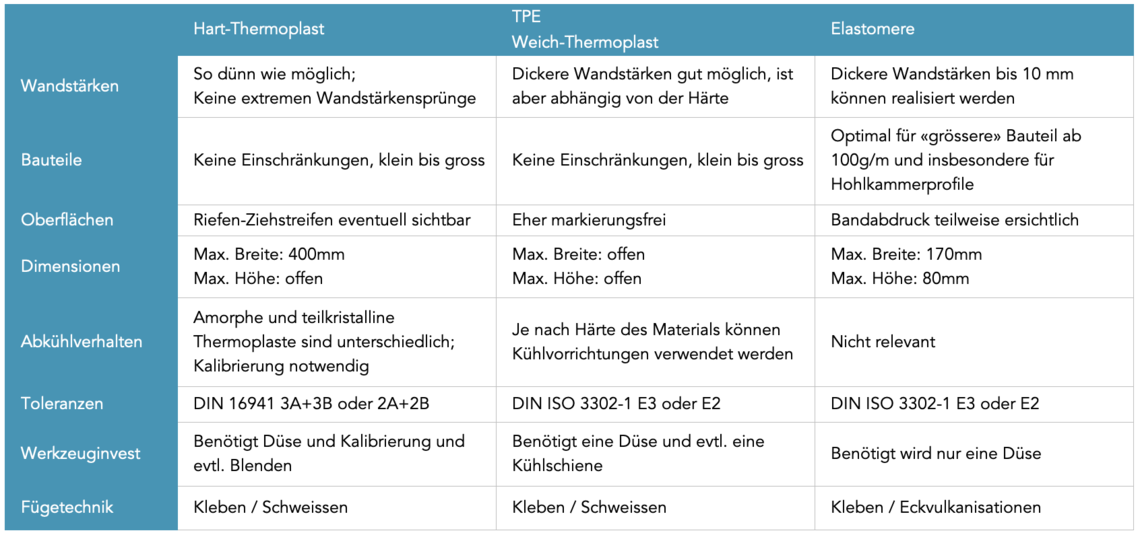

The extrusion process can be used to process hard and soft thermoplastics as well as elastomers. Endless molded parts and semi-finished products can be produced from the various plastics. To ensure that the quality of the end products meets our high standards, a machine design that is tailored to the material is crucial. Depending on the material, we use a water bath, a spray bath or vulcanization. The following overview shows you the various requirements that hard and soft thermoplastics and elastomers entail in the manufacturing process.