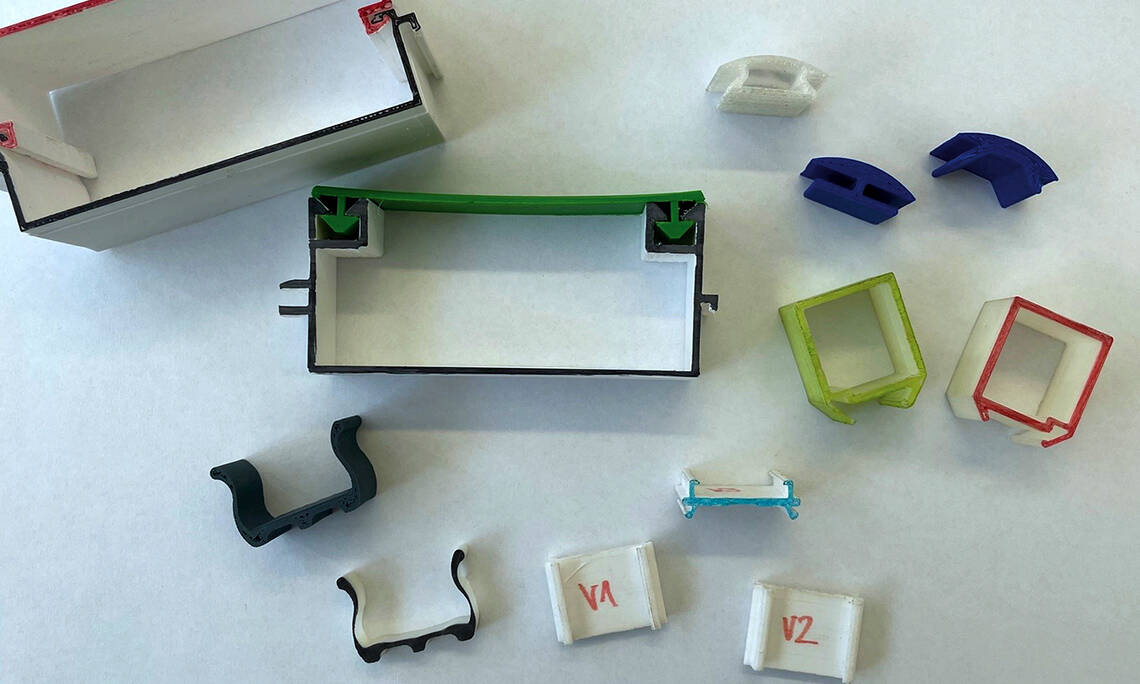

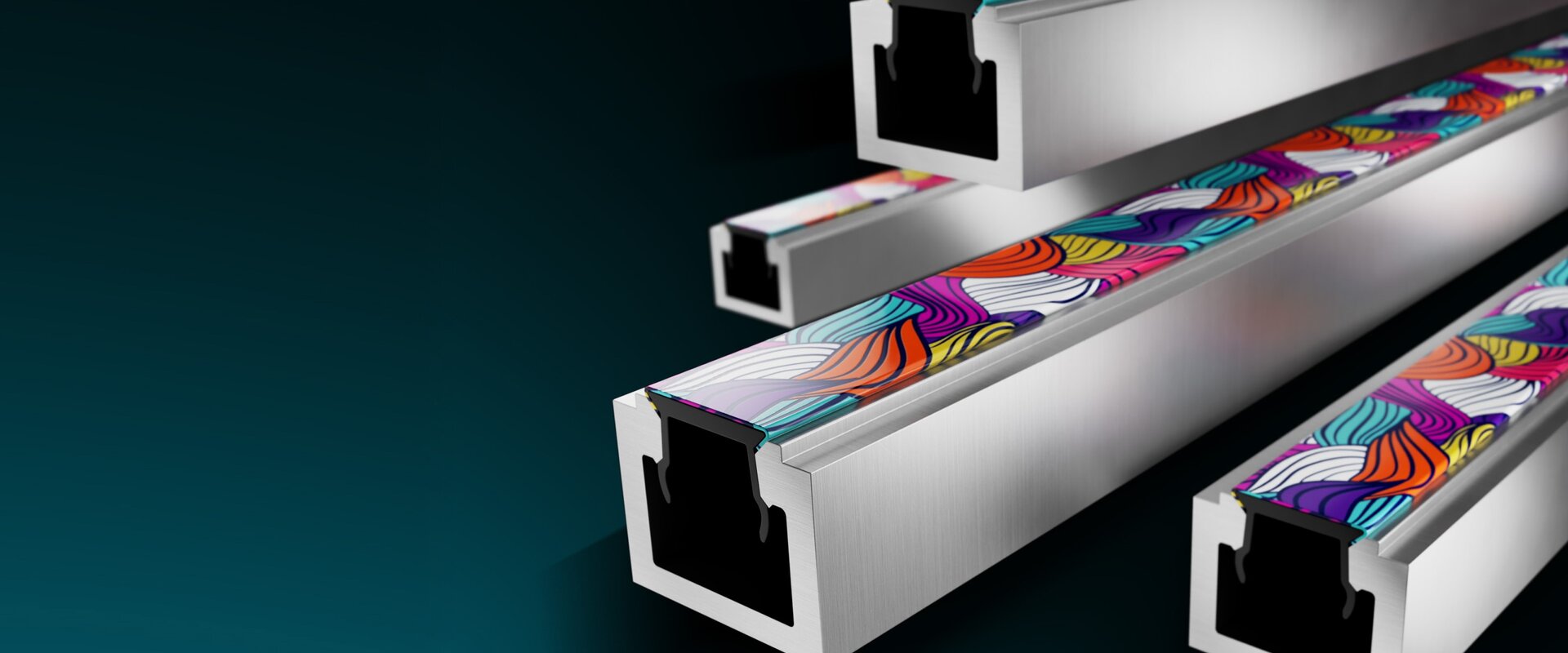

Mobil Kunststoffprofile AG now uses two 3D printers with which various plastic materials can be processed. This opens up major time advantages, particularly in the development phase of new profiles.

With 3D printing technology, also known as additive manufacturing, we offer our customers a new opportunity to develop profiles of the highest quality within a short period of time. Since commissioning two 3D printers, we have already been able to realize various projects and test and evaluate additively manufactured prototypes. Subsequent tool corrections could be completely avoided thanks to the prototypes created, which resulted in significant time savings. With our expertise in plastic materials and extrusion, we will now make greater use of this technology and develop it further. You too can benefit from the many advantages that 3D printing offers for the development of profiles with a profile.